Innovative Analytical & Automation Solutions for the Dairy Industry from Bentley Instruments

TECHNOPATH partners with Bentley Instruments, who have specialised in the design and development of analytical solutions for the profit optimisation of milk and dairy products (cream, serum, retentate, yoghurt, ice cream, …) for more than 35 years. Their solutions allow you to ensure optimal and rapid quality control in order to perfect your manufacturing process or herds management.

The Bentley Instruments product line includes a wide range of instrumentation for the dairy industry. Every model is designed for maximum productivity, accuracy and reliability. The instruments are in use in over 45 countries around the world and are backed by global service teams that are available 24-7.

We also offer solutions for the milk analysers and laboratories automation to ensure complete methods standardisation as well as a systematic and optimised analytical evaluation of each sample. The goal of this new holistic approach is to provide new tools for the optimal qualitative and economic profit optimisation of your production processes or herds management

Service Excellence

TECHNOPATH provides full support and servicing with all Bentley Instrumentation. Spare parts can also be ordered through TECHNOPATH.

Technologies for the Dairy Industry

Measurement of fat, protein, lactose and solids.

The component analysis models are designed to measure and calculate milk and dairy components, including: fat A&B, protein, lactose, total solids (TS), solids-non-fat (SNF), urea, milk urea nitrogen (MUN), free fatty acids (FFA), freezing point depression (FPD), added water, pH and a host of other parameters. The technology for analysis utilises the molecular-bond energy absorptions found in the mid-infrared spectrum. Three different models are available for component analysis:

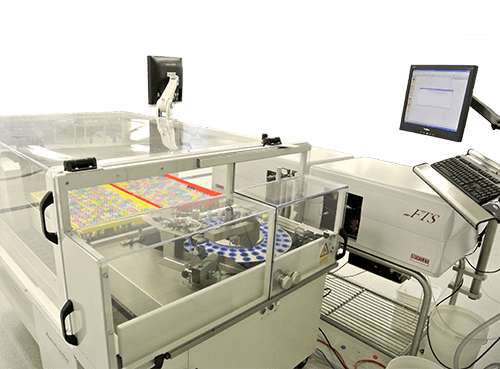

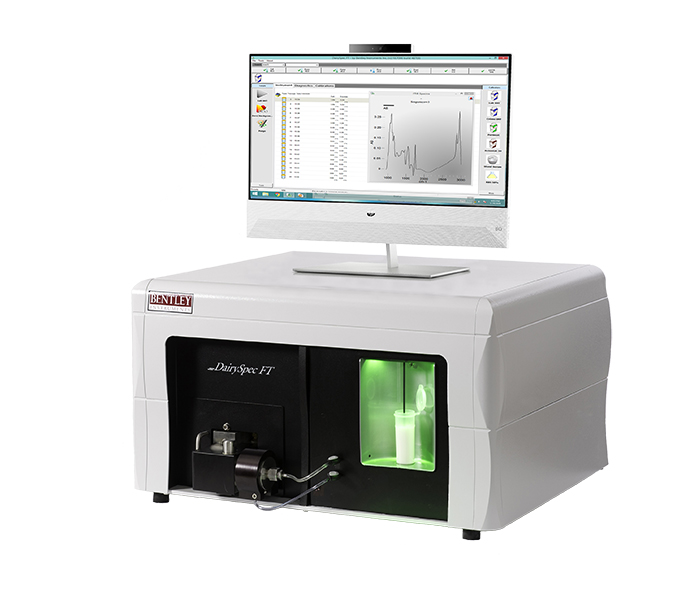

DairySpec FT: Infrared Analysers

Semi-Automatic and Automatic versions from 100 up to 300 Samples/hr.

Measures: fat, protein, lactose, solids and more.

DairySpec Combi Series: DairySpec FT & SomaCount FC

Automatic versions from 100 up to 300 Samples/hr.

Measures: fat, protein, lactose, solids and early mastitis detection.

Combi FTS Series: Infrared Analyser (FTS) & Somatic Cells Counter (FCM)

Semi-Automatic and Automatic versions from 400 up to 600 Samples/hr.

Analyse the chemical composition (up to 64 parameters).

Bentley Instruments is a recognized industry leader in reliable and precise determination of somatic cell counts in all types of raw milk. We offer two basic models as well as combination systems, making it easy to select the right instrument for your operation:

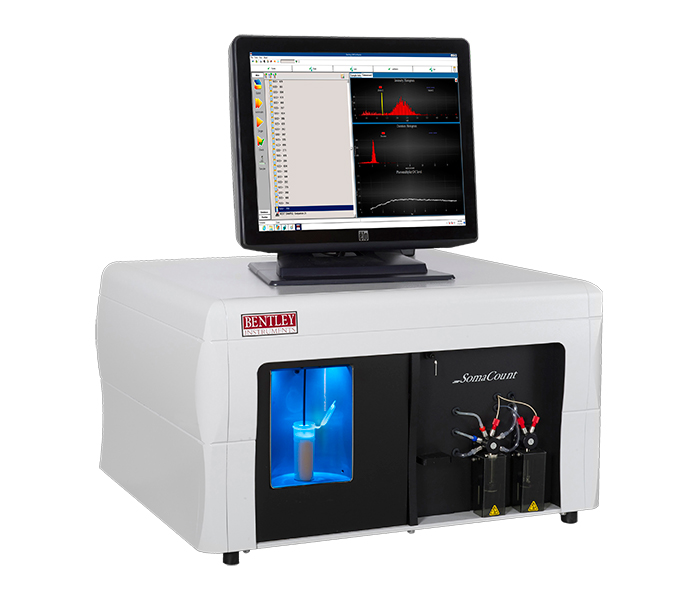

SomaCount FC: Somatic Cell Counters

Semi-Automatic and Automatic versions from 100 up to 300 Samples/hr.

Early mastitis detection.

DairySpec Combi Series: DairySpec FT & SomaCount FC

Automatic versions from 100 up to 300 Samples/hr.

Measures: fat, protein, lactose, solids and early mastitis detection.

Combi FTS Series: Infrared Analyser (FTS) & Somatic Cells Counter (FCM)

Semi-Automatic and Automatic versions from 400 up to 600 Samples/hr.

Analyse the chemical composition (up to 64 parameters).

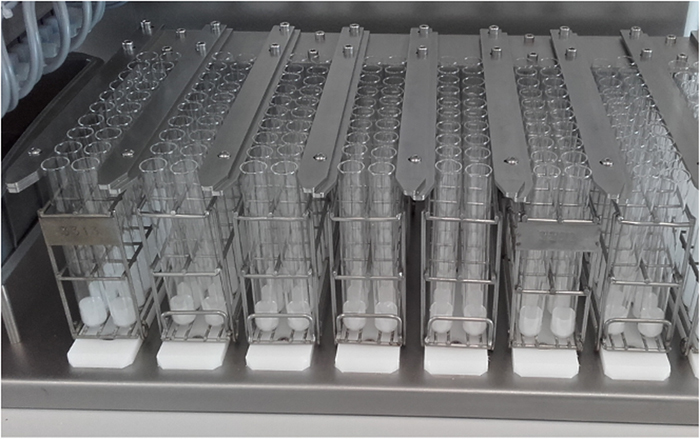

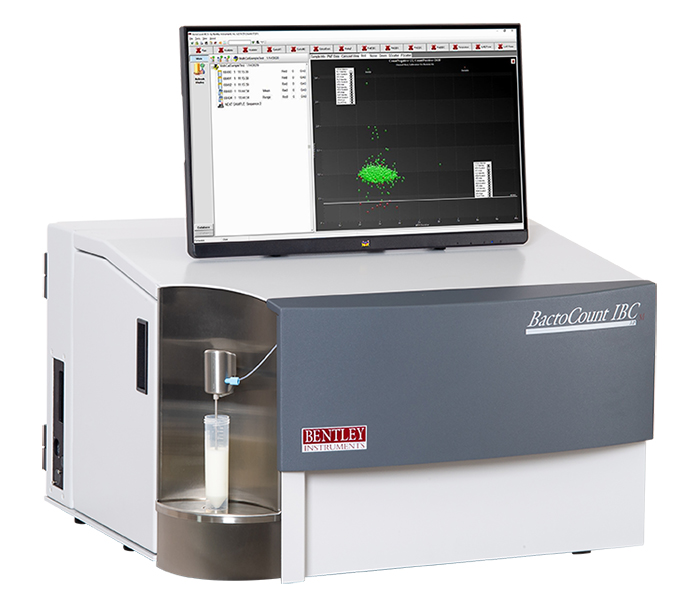

BactoCount IBCm: Bacteria (ISO 16140-2:2016) & Somatic Cells Counter

Semi-Automatic version up to 50 Analyses/hr.

Total bacteria count and somatic cell content.

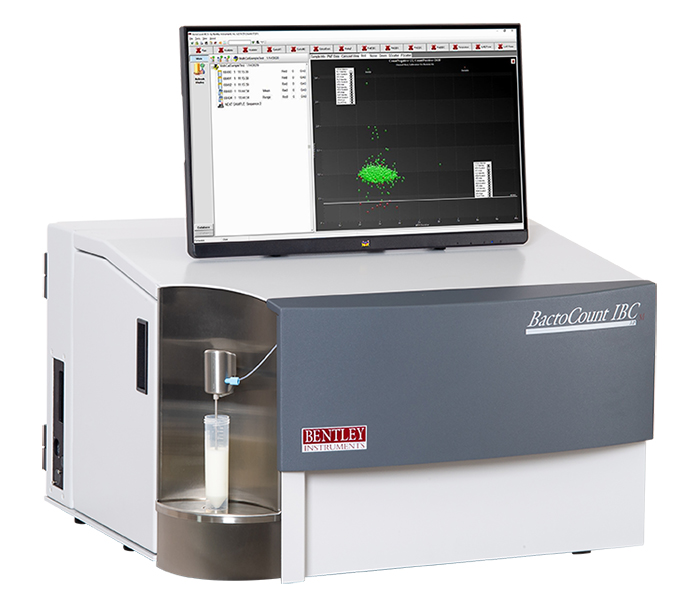

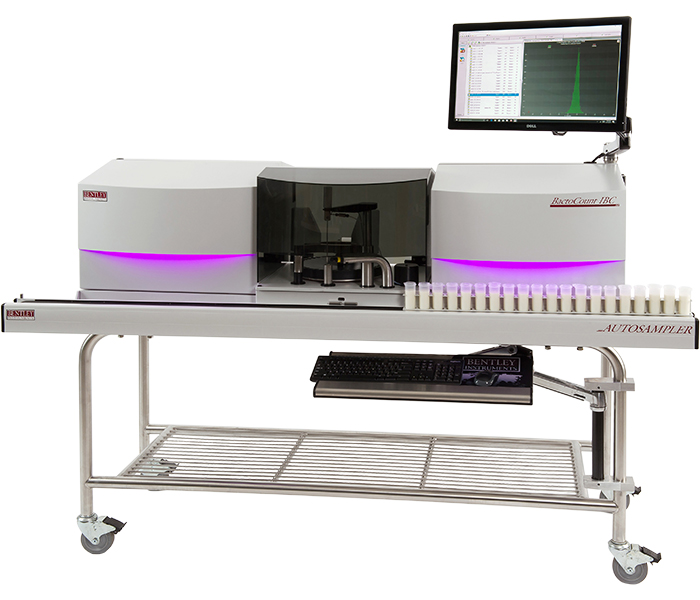

BactoCount IBC: Bacteria (ISO 16140-2:2016) & Somatic Cells Counter

Automatic version up to 50 to 200 Analyses/hr.

Total bacteria count and somatic cell content.

The IBC series uses flow cytometry for the rapid enumeration of total bacteria in milk. They are the ideal solution for any processing plant or test laboratory involved in quality assessment of milk.

Two IBC models are available, making it easy to select an instrument that fits the needs of your workflow. Click on a model name for a detailed overview of each instrument.

BactoCount IBCm: Bacteria (ISO 16140-2:2016) & Somatic Cells Counter

Semi-Automatic version up to 50 Analyses/hr.

Total bacteria count and somatic cell content.

BactoCount IBC: Bacteria (ISO 16140-2:2016) & Somatic Cells Counter

Automatic version up to 50 to 200 Analyses/hr.

Total bacteria count and somatic cell content.

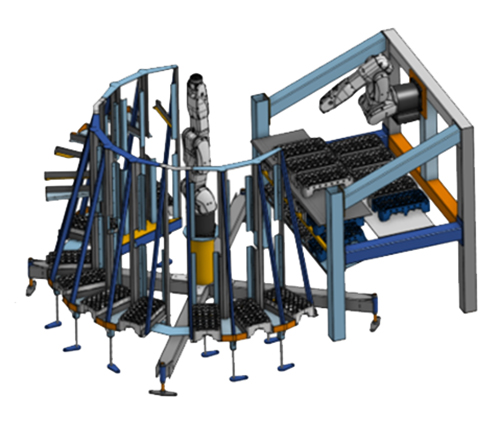

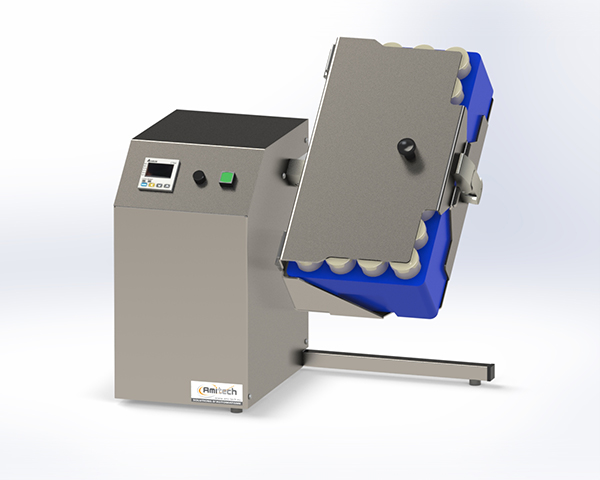

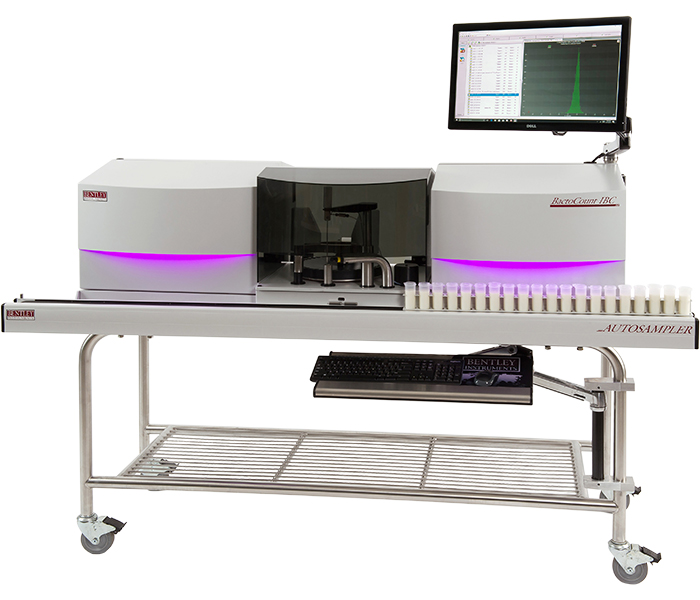

Optimal & Individualised Valorisation of each Sample.

Bentley Instruments also offer solutions for the milk analyzers and laboratories automation to ensure complete methods standardization as well as a systematic and optimized analytical evaluation of each sample. The goal of this new holistic approach is to provide new tools for the optimal qualitative and economic valorisation of your production processes or herds management.