-

Accelerate assay optimisation, simplify regulatory compliance, and ensure quality. Understand and manage the performance of your automated liquid handlers, multichannel pipettes, labware, operators, and more. Compatible with virtually all automated liquid handling systems and multichannel handheld pipettes, the Artel MVS sits on a mobile workstation for portable rapid calibration, verifications and optimization of dispensed volumes with high precision and accuracy. The MVS’s unique, dual-dye photometric measurements are robust against environmental influences and traceable to SI units to enable comparison across operators, protocols, equipment, and locations. Using the Calibrator Plate, Verification Plates, and an Artel-certified Plate Reader, the MVS supports an unbroken chain of traceability to national and international standards.

Accelerate assay optimisation, simplify regulatory compliance, and ensure quality. Understand and manage the performance of your automated liquid handlers, multichannel pipettes, labware, operators, and more. Compatible with virtually all automated liquid handling systems and multichannel handheld pipettes, the Artel MVS sits on a mobile workstation for portable rapid calibration, verifications and optimization of dispensed volumes with high precision and accuracy. The MVS’s unique, dual-dye photometric measurements are robust against environmental influences and traceable to SI units to enable comparison across operators, protocols, equipment, and locations. Using the Calibrator Plate, Verification Plates, and an Artel-certified Plate Reader, the MVS supports an unbroken chain of traceability to national and international standards. -

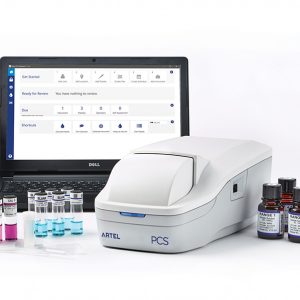

Ensure data integrity, reliable test results, and regulatory compliance. Easily calibrate pipettes, perform interim verifications, standardise operator skills, manage pipette inventory, and more with the Artel PCS® Pipette Calibration System. Fast, accurate, and precise, the PCS is a portable and easy-to-use volume verification system that simplifies single-channel pipette calibration, interim volume verification, and pipette user/operator training and competency assessment. Paired with the included PCS Software, the PCS helps you stay on top of your pipette inventory with calibration and interim verification scheduling, email notifications, pipette and pipette operator status, and comprehensive, auditable documentation. Easily meet both external regulatory requirements and internal quality standards to ensure data quality. The power of the PCS stems from the ratiometric photometry technology and standardised dye solutions that are used to measure dispensed volumes. The system is robust against differences in environmental conditions and calibration results are traceable to NIST standards, enabling straightforward comparison of pipettes, operators, methods, and locations.

Ensure data integrity, reliable test results, and regulatory compliance. Easily calibrate pipettes, perform interim verifications, standardise operator skills, manage pipette inventory, and more with the Artel PCS® Pipette Calibration System. Fast, accurate, and precise, the PCS is a portable and easy-to-use volume verification system that simplifies single-channel pipette calibration, interim volume verification, and pipette user/operator training and competency assessment. Paired with the included PCS Software, the PCS helps you stay on top of your pipette inventory with calibration and interim verification scheduling, email notifications, pipette and pipette operator status, and comprehensive, auditable documentation. Easily meet both external regulatory requirements and internal quality standards to ensure data quality. The power of the PCS stems from the ratiometric photometry technology and standardised dye solutions that are used to measure dispensed volumes. The system is robust against differences in environmental conditions and calibration results are traceable to NIST standards, enabling straightforward comparison of pipettes, operators, methods, and locations. -

Introducing the ILAS 4000 Robot The new ILAS 4000 robot is a unique solution to automate and standardise sample preparation for bacteria counters up to a maximum speed of 200 samples/hour. Fully refrigerated, samples are identified (RFID chips or barcode), homogenised, uncapped and analysed. The vials are automatically recapped after analysis and place back in their original tray position. Compatible with the BactoCount IBC Series: Bacteria & Somatic Cells Counter and alternative methods. The Standardisation Tray used for Laboratory Automation is compatible with the ILAS Robot.

Introducing the ILAS 4000 Robot The new ILAS 4000 robot is a unique solution to automate and standardise sample preparation for bacteria counters up to a maximum speed of 200 samples/hour. Fully refrigerated, samples are identified (RFID chips or barcode), homogenised, uncapped and analysed. The vials are automatically recapped after analysis and place back in their original tray position. Compatible with the BactoCount IBC Series: Bacteria & Somatic Cells Counter and alternative methods. The Standardisation Tray used for Laboratory Automation is compatible with the ILAS Robot. -

Introducing the ILAS 3000 Robot The combination of the Bentley Instruments and high-tech robotics allows the complete automation and standardisation of the analytical chain and MSDs reduction. With the ILAS 3000 Robot, an operator can manage up to 3 lines simultaneously. Always with a goal of enhanced productivity and standardisation, this system analyses up to 600 samples/hour. Compatible with the Combi FTS Series: Infrared Analyser & Somatic Cells Counter and alternative methods. The Standardisation Tray used for Laboratory Automation is compatible with the ILAS Robot.

Introducing the ILAS 3000 Robot The combination of the Bentley Instruments and high-tech robotics allows the complete automation and standardisation of the analytical chain and MSDs reduction. With the ILAS 3000 Robot, an operator can manage up to 3 lines simultaneously. Always with a goal of enhanced productivity and standardisation, this system analyses up to 600 samples/hour. Compatible with the Combi FTS Series: Infrared Analyser & Somatic Cells Counter and alternative methods. The Standardisation Tray used for Laboratory Automation is compatible with the ILAS Robot. -

Real-Time enumeration of individual Bacteria & Somatic Cells in raw milk Automatic milk analysis at 200 samples/hour The BactoCount series (50, 100, 150, 200) uses flow cytometry for the real-time determination of total flora and somatic cells in raw milk up to a maximum speed of 200 analysis/hour. The high speed of this model makes it the ideal solution for mid to large size laboratories that need an easy to maintain, exceptionally fast bacteria counting system. The BactoCount IBC Series uses a proprietary process based on flow cytometry for the rapid, highly accurate, reliable and multiplex enumeration of individual bacteria and somatic cells in raw milk. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 4000 ROBOT: Automation System for Bacteria Counter

Real-Time enumeration of individual Bacteria & Somatic Cells in raw milk Automatic milk analysis at 200 samples/hour The BactoCount series (50, 100, 150, 200) uses flow cytometry for the real-time determination of total flora and somatic cells in raw milk up to a maximum speed of 200 analysis/hour. The high speed of this model makes it the ideal solution for mid to large size laboratories that need an easy to maintain, exceptionally fast bacteria counting system. The BactoCount IBC Series uses a proprietary process based on flow cytometry for the rapid, highly accurate, reliable and multiplex enumeration of individual bacteria and somatic cells in raw milk. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 4000 ROBOT: Automation System for Bacteria Counter -

Real-Time enumeration of individual Bacteria & Somatic Cells in raw milk Semi-Automatic version up to 50 analysis/hour The new BactoCount IBCm 3.0 is a semi-automated instrument that uses a proprietary process based on next-generation flow cytometry for the rapid, highly accurate, reliable and multiplex enumeration of individual bacteria and somatic cells in raw milk. The rapid test for bacteria and somatic cells makes it the ideal solution for any processing plant or laboratory involved in the quality assessment of milk. The instrument offers multiplex applications thanks to its unique dedicated platform. Up to two applications can be run simultaneously on a given sample. The overall design of the instrument has also been designed to allow ease of access and maintenance. With this in mind, IBCm 3.0 embeds a new kinetic, self aligned flow cell mounting system. The BactoCount IBCm 3.0 can be equipped with a conveyor, automating the sampling at a maximum rate of 50 analysis/hour. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 4000 ROBOT: Automation System for Bacteria Counter

Real-Time enumeration of individual Bacteria & Somatic Cells in raw milk Semi-Automatic version up to 50 analysis/hour The new BactoCount IBCm 3.0 is a semi-automated instrument that uses a proprietary process based on next-generation flow cytometry for the rapid, highly accurate, reliable and multiplex enumeration of individual bacteria and somatic cells in raw milk. The rapid test for bacteria and somatic cells makes it the ideal solution for any processing plant or laboratory involved in the quality assessment of milk. The instrument offers multiplex applications thanks to its unique dedicated platform. Up to two applications can be run simultaneously on a given sample. The overall design of the instrument has also been designed to allow ease of access and maintenance. With this in mind, IBCm 3.0 embeds a new kinetic, self aligned flow cell mounting system. The BactoCount IBCm 3.0 can be equipped with a conveyor, automating the sampling at a maximum rate of 50 analysis/hour. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 4000 ROBOT: Automation System for Bacteria Counter -

Why wait? TECHNOPATH partners with CertaBlue for their rapid microbiology technology. CertaBlue is based on rapid detection of several metabolic processes that take place within the growing organism. The system can detect colour changes through highly sensitive optical sensors. All vials are ready to use, prefilled with media and equipped with CertaBlue sensors. In most cases, the vials can be inoculated with a non-diluted high volume sample. The CertaBlue vials contain an optical sensor, which can detect carbon dioxide as the universal indicator for microbial growth. The sensor is placed in the bottom of the vial, where it directly detects carbon dioxide changes. CertaBlue sensors are only permeable for gases. Liquids, dyed / heavily coloured products and other particles can’t falsify results. What can CertaBlue offer you:

Why wait? TECHNOPATH partners with CertaBlue for their rapid microbiology technology. CertaBlue is based on rapid detection of several metabolic processes that take place within the growing organism. The system can detect colour changes through highly sensitive optical sensors. All vials are ready to use, prefilled with media and equipped with CertaBlue sensors. In most cases, the vials can be inoculated with a non-diluted high volume sample. The CertaBlue vials contain an optical sensor, which can detect carbon dioxide as the universal indicator for microbial growth. The sensor is placed in the bottom of the vial, where it directly detects carbon dioxide changes. CertaBlue sensors are only permeable for gases. Liquids, dyed / heavily coloured products and other particles can’t falsify results. What can CertaBlue offer you:- Simplified test procedures

- Ready-to-use vials including media and CertaBlue sensor

- Test procedure consists of just adding your sample to the vial

- Results in hours instead of days

- Real-time detection and early warning of positive samples

- Ensures a quick and safe product release

- Better recovery of injured and / or damaged microorganisms

-

Rapid, Automated and Remote Microbial Testing for Water and Food Safety Colifast ALARM™ is an electronic instrument for detecting indicator bacteria in drinking water using patented Colifast technology. 100 ml water samples are automatically collected at programmed intervals and analyzed for total coliforms, thermotolerant coliform bacteria or E. coli. In addition to performing rapid, online microbial water analysis, Colifast ALARM measures water turbidity. The system can automatically send results to control rooms / operators via LAN, digital signals or via mobile networks (SMS). The system can detect down to 1 cfu / 100 mL, and results are achieved within 6-14 / 15 hours. Technology The main components of Colifast ALARM are the incubator chamber, an injection pump system for fluid handling, and a detector system that includes wavelength-specific emitters combined with a spectrometer. Detection of down to 1 viable target bacteria is based on bacterial growth, group-specific enzyme activity and measured concentrations of a fluorescent product (ppb MU). An increase in the number of target bacteria means an increase in the amount of β-D-glucuronidase (E. coli-specific enzyme). The enzyme hydrolyses the growth medium substrate to MU (the fluorescent product) and β-D-glucuronic acid. Increased MU release gives increased fluorescence signal on the Colifast ALARM. Colifast growth medium contains inhibitors to prevent growth of non-coliforms. Colifast ALARM is verified by EPA's ETV program.

Rapid, Automated and Remote Microbial Testing for Water and Food Safety Colifast ALARM™ is an electronic instrument for detecting indicator bacteria in drinking water using patented Colifast technology. 100 ml water samples are automatically collected at programmed intervals and analyzed for total coliforms, thermotolerant coliform bacteria or E. coli. In addition to performing rapid, online microbial water analysis, Colifast ALARM measures water turbidity. The system can automatically send results to control rooms / operators via LAN, digital signals or via mobile networks (SMS). The system can detect down to 1 cfu / 100 mL, and results are achieved within 6-14 / 15 hours. Technology The main components of Colifast ALARM are the incubator chamber, an injection pump system for fluid handling, and a detector system that includes wavelength-specific emitters combined with a spectrometer. Detection of down to 1 viable target bacteria is based on bacterial growth, group-specific enzyme activity and measured concentrations of a fluorescent product (ppb MU). An increase in the number of target bacteria means an increase in the amount of β-D-glucuronidase (E. coli-specific enzyme). The enzyme hydrolyses the growth medium substrate to MU (the fluorescent product) and β-D-glucuronic acid. Increased MU release gives increased fluorescence signal on the Colifast ALARM. Colifast growth medium contains inhibitors to prevent growth of non-coliforms. Colifast ALARM is verified by EPA's ETV program. -

The Colifast At-Line Monitor – CALM is a fully automated early warning system for monitoring of coliforms and Pseudomonas aeruginosa in water. Detection time ranges from 2 to 12 hours. The technology is time-saving, cost-reducing, and environmentally friendly. Examples of CALM applications are monitoring of raw water, in-process water, waste water and recreational water. No laboratory facilities and minimal skills in microbiology are required to operate the instrument. The Colifast CALM is easily connected to the system computer or LAN interface. The patented Colifast growth media are supplied in Pre-filled Multi Well Trays™ and the flexibility of the system makes it easy to adapt to different applications. The CALM can perform parallel analysis of different target organisms. Depending on method and test frequency, the CALM needs monthly or weekly refilling of reagents. Technology The CALM instrument detects and quantifies E. coli, fecal or total coliform bacteria in water by fluorometric monitoring of β-glucuronidase activity (E. coli) or β-galactosidase activity (fecal and total coliforms). The detection of P. aeruginosa is based on substrate hydrolysis of aminopeptidase enzymes present in this bacterium. The Colifast technology is comprised of unique media formulations combined with instrument detection systems. The technology is covered by patents in numerous countries, with several international patents pending. Growth of other bacteria is stopped by inhibitors in the medium and by incubation of the samples at high temperature: Incubator temperatures for selection of thermotolerant coliform bacteria are 44 ° C and total coliforms / E. coli are 37 ° C. Method The instrument can perform one of two methods at a time. The Most Probable Number (MPN) method is based on the cultivation of bacteria. A certain volume is added to 4-6 wells of growth medium and the bacterial number is determined from how many of the wells that gave growth after the incubation period (11-12 hours). For the results to be as accurate as possible, it is therefore important that the samples taken on a given source usually give a mixture of positive and negative results. The rapid method is also a quantitative method, which is based on the enzyme activity of the bacteria present in the water sample. It provides response after 75-115 min and is suitable for water sources where major contamination events can occur. The CALM is a flexible instrument. This means that the instrument can be adapted to different locations with different occurrence of bacteria. If a source has an average bacterial count of 500 cfu / 100ml, 0.2 ml will usually give a positive test. By injecting about half of this volume, you will often get both positive and negative samples. If the source has lower concentrations of bacteria, the media concentration can be changed so that the sample volume can be as high as 10 ml. In this way, we ensure good results from the CALM instrument with optimal concentration of media after addition of sample and a sample volume appropriate for the source being measured.

The Colifast At-Line Monitor – CALM is a fully automated early warning system for monitoring of coliforms and Pseudomonas aeruginosa in water. Detection time ranges from 2 to 12 hours. The technology is time-saving, cost-reducing, and environmentally friendly. Examples of CALM applications are monitoring of raw water, in-process water, waste water and recreational water. No laboratory facilities and minimal skills in microbiology are required to operate the instrument. The Colifast CALM is easily connected to the system computer or LAN interface. The patented Colifast growth media are supplied in Pre-filled Multi Well Trays™ and the flexibility of the system makes it easy to adapt to different applications. The CALM can perform parallel analysis of different target organisms. Depending on method and test frequency, the CALM needs monthly or weekly refilling of reagents. Technology The CALM instrument detects and quantifies E. coli, fecal or total coliform bacteria in water by fluorometric monitoring of β-glucuronidase activity (E. coli) or β-galactosidase activity (fecal and total coliforms). The detection of P. aeruginosa is based on substrate hydrolysis of aminopeptidase enzymes present in this bacterium. The Colifast technology is comprised of unique media formulations combined with instrument detection systems. The technology is covered by patents in numerous countries, with several international patents pending. Growth of other bacteria is stopped by inhibitors in the medium and by incubation of the samples at high temperature: Incubator temperatures for selection of thermotolerant coliform bacteria are 44 ° C and total coliforms / E. coli are 37 ° C. Method The instrument can perform one of two methods at a time. The Most Probable Number (MPN) method is based on the cultivation of bacteria. A certain volume is added to 4-6 wells of growth medium and the bacterial number is determined from how many of the wells that gave growth after the incubation period (11-12 hours). For the results to be as accurate as possible, it is therefore important that the samples taken on a given source usually give a mixture of positive and negative results. The rapid method is also a quantitative method, which is based on the enzyme activity of the bacteria present in the water sample. It provides response after 75-115 min and is suitable for water sources where major contamination events can occur. The CALM is a flexible instrument. This means that the instrument can be adapted to different locations with different occurrence of bacteria. If a source has an average bacterial count of 500 cfu / 100ml, 0.2 ml will usually give a positive test. By injecting about half of this volume, you will often get both positive and negative samples. If the source has lower concentrations of bacteria, the media concentration can be changed so that the sample volume can be as high as 10 ml. In this way, we ensure good results from the CALM instrument with optimal concentration of media after addition of sample and a sample volume appropriate for the source being measured. -

Colifast Field Kit is a portable tool for field detection of coliform bacteria in water. The main method of the kit is a rapid method that provides an answer as early as 15 minutes, 2 hours at the latest. In addition, the kit includes methods for a quantitative MPN (Most Probable Number) method and presence/absence results. The procedure is very easy to perform, and requires no laboratory skills. Colifast Field Kit is delivered in a robust and portable metal case, and all equipment required for the water analysis is included. The Colifast Micro Detector (CMD) is used in combination with a growth medium for specific detection of target bacteria. Combined, they provide a simple instrumental analysis and rapid results that quantify the amount of coliform and thermotolerant bacteria in water. The method is based upon the patented technology of Colifast AS. The system detects down to 1 target bacterium per sample volume. Method The Colifast technology is based on a chemical reaction between a substrate in the growth medium and enzymes produced by the coliform bacteria. The bacterial enzyme β-D-galactosidase hydrolyses the substrate 4-methylumbelliferyl-β-D-galactoside, which results in the release of the fluorescent product 4-methylumbelliferone (MU). In addition to substrate, activators and growth factors, the medium comprises inhibitors that prevent the growth of non-coliform bacteria. The results are measured in fluorescent units. An increase in the number of bacteria corresponds to an increased amount of β-D-galactosidase (enzyme). The subsequent increase in the amount of MU (fluorescent product) results in a higher value on the instrument (Colifast Micro Detector). The incubation temperature selects for thermotolerant coliforms at 44 °C and total coliforms at 37 °C.

Colifast Field Kit is a portable tool for field detection of coliform bacteria in water. The main method of the kit is a rapid method that provides an answer as early as 15 minutes, 2 hours at the latest. In addition, the kit includes methods for a quantitative MPN (Most Probable Number) method and presence/absence results. The procedure is very easy to perform, and requires no laboratory skills. Colifast Field Kit is delivered in a robust and portable metal case, and all equipment required for the water analysis is included. The Colifast Micro Detector (CMD) is used in combination with a growth medium for specific detection of target bacteria. Combined, they provide a simple instrumental analysis and rapid results that quantify the amount of coliform and thermotolerant bacteria in water. The method is based upon the patented technology of Colifast AS. The system detects down to 1 target bacterium per sample volume. Method The Colifast technology is based on a chemical reaction between a substrate in the growth medium and enzymes produced by the coliform bacteria. The bacterial enzyme β-D-galactosidase hydrolyses the substrate 4-methylumbelliferyl-β-D-galactoside, which results in the release of the fluorescent product 4-methylumbelliferone (MU). In addition to substrate, activators and growth factors, the medium comprises inhibitors that prevent the growth of non-coliform bacteria. The results are measured in fluorescent units. An increase in the number of bacteria corresponds to an increased amount of β-D-galactosidase (enzyme). The subsequent increase in the amount of MU (fluorescent product) results in a higher value on the instrument (Colifast Micro Detector). The incubation temperature selects for thermotolerant coliforms at 44 °C and total coliforms at 37 °C. -

Rapid & accurate determination of Somatic Cells and Chemical Composition in raw milk Automatic milk analysis at 600 samples/hour Engineered in accordance with Bentley Instruments’ rigorous design principles, the FTS combi provides precise and accurate measurements. The FTS combi comprises two separate modules — the Bentley Flow Cytometer (FCM), and the Bentley Fourier Transform Spectrometer (FTS). The FCM measures the somatic cell count of the milk samples while the FTS simultaneously measures the milk composition up to 64 parameters (fat, protein, lactose, casein, fatty acids profil, minerals, blood BHB,...). After first being stirred, the milk is drawn from a sample vial and delivered to both measurement modules. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. 3M™ Clean-Trace™ Surface ATP UXL100 3M™ Clean-Trace™ Water Plus - Total ATP AQT200 3M™ Clean-Trace™ Water - Free ATP AQF100

Rapid & accurate determination of Somatic Cells and Chemical Composition in raw milk Automatic milk analysis at 600 samples/hour Engineered in accordance with Bentley Instruments’ rigorous design principles, the FTS combi provides precise and accurate measurements. The FTS combi comprises two separate modules — the Bentley Flow Cytometer (FCM), and the Bentley Fourier Transform Spectrometer (FTS). The FCM measures the somatic cell count of the milk samples while the FTS simultaneously measures the milk composition up to 64 parameters (fat, protein, lactose, casein, fatty acids profil, minerals, blood BHB,...). After first being stirred, the milk is drawn from a sample vial and delivered to both measurement modules. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. 3M™ Clean-Trace™ Surface ATP UXL100 3M™ Clean-Trace™ Water Plus - Total ATP AQT200 3M™ Clean-Trace™ Water - Free ATP AQF100 -

Rapid and accurate determination of milk products chemical composition Semi-automatic and automatic versions from 100 up to 300 samples/hour The DairySpec FT uses FTIR spectroscopy for extremely accurate and reliable milk and dairy products chemical composition determination. Analysing up to 64 parameters simultaneously, the DairySpec FT is the optimal solution for the quality control of raw and processed materials. It gives access to the very fine analysis of milk and dairy products chemical composition (fat, proteins, casein, lactose, solids, urea, citric acid, fatty acids profil, FPD). Highly reliable and accurate for milk (raw, UHT, ...) and dairy products (cream, whey, permeate, retentate, ...) analysis. Adaptable to measure other products and parameters upon request. The spectra are standardised in real time to optimise calibrations transferability, stability and qualitative analysis (adulteration). Direct access to spectra for the development of new calibrations. 3M™ Clean-Trace™ Surface ATP UXL100 3M™ Clean-Trace™ Water Plus - Total ATP AQT200 3M™ Clean-Trace™ Water - Free ATP AQF100

Rapid and accurate determination of milk products chemical composition Semi-automatic and automatic versions from 100 up to 300 samples/hour The DairySpec FT uses FTIR spectroscopy for extremely accurate and reliable milk and dairy products chemical composition determination. Analysing up to 64 parameters simultaneously, the DairySpec FT is the optimal solution for the quality control of raw and processed materials. It gives access to the very fine analysis of milk and dairy products chemical composition (fat, proteins, casein, lactose, solids, urea, citric acid, fatty acids profil, FPD). Highly reliable and accurate for milk (raw, UHT, ...) and dairy products (cream, whey, permeate, retentate, ...) analysis. Adaptable to measure other products and parameters upon request. The spectra are standardised in real time to optimise calibrations transferability, stability and qualitative analysis (adulteration). Direct access to spectra for the development of new calibrations. 3M™ Clean-Trace™ Surface ATP UXL100 3M™ Clean-Trace™ Water Plus - Total ATP AQT200 3M™ Clean-Trace™ Water - Free ATP AQF100 -

Simultaneous Somatic Cell and Component Analysis Automatic versions from 100 up to 300 samples/hour System that combines the DairySpec FT for component analysis and the SomaCount FC for Somatic Cell Counting. The combination of these two flagship methods provides a complete overview of milk chemical and hygienic composition by analysing up to 64 parameters simultaneously. Different versions of DairySpec Combi are available (100, 150, 200, 250, 300) up to a maximum speed of 300 samples/hour. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 3000 ROBOT: Automation System for Milk Analysers

Simultaneous Somatic Cell and Component Analysis Automatic versions from 100 up to 300 samples/hour System that combines the DairySpec FT for component analysis and the SomaCount FC for Somatic Cell Counting. The combination of these two flagship methods provides a complete overview of milk chemical and hygienic composition by analysing up to 64 parameters simultaneously. Different versions of DairySpec Combi are available (100, 150, 200, 250, 300) up to a maximum speed of 300 samples/hour. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler. Compatible with the ILAS 3000 ROBOT: Automation System for Milk Analysers -

Hands-on training & performance verification improves pathogen detection. Data collected from environmental sampling of surfaces is highly dependent on the operator. Understanding and quantitatively characterising the percent recovery and consistency of sample collection by an operator drives improved detection and prevention of pathogens. Performance verification involves determining the percent recovery and consistency of an operator who collects samples in an environmental sampling program. Introducing Enverify™, a quantitative positive control for environmental sampling programs and comprises a flat substrate with a specific quantity of viable microorganisms coated on the surface. The microbes are safe-to-handle and are coated across a 10 cm x 10 cm area. Enverify™ provides a standardised tool for hands-on training and performance verification of operators that collect samples in environmental sampling programs. Enverify™ is compatible with contact plates, swab sampling devices, and sponge sample devices. Activities Involving Environmental Sampling:

Hands-on training & performance verification improves pathogen detection. Data collected from environmental sampling of surfaces is highly dependent on the operator. Understanding and quantitatively characterising the percent recovery and consistency of sample collection by an operator drives improved detection and prevention of pathogens. Performance verification involves determining the percent recovery and consistency of an operator who collects samples in an environmental sampling program. Introducing Enverify™, a quantitative positive control for environmental sampling programs and comprises a flat substrate with a specific quantity of viable microorganisms coated on the surface. The microbes are safe-to-handle and are coated across a 10 cm x 10 cm area. Enverify™ provides a standardised tool for hands-on training and performance verification of operators that collect samples in environmental sampling programs. Enverify™ is compatible with contact plates, swab sampling devices, and sponge sample devices. Activities Involving Environmental Sampling:- Environmental monitoring for pathogens or indicator organisms

- Sanitation verification using ATP or indicator organisms

- Verification of hygienic restoration following adverse events

- Verification of containment during construction activities

-

Test gram negative and gram positive bacteria in the same test panel TECHNOPATH partners with Biolog for rapid and accurate identification of over 2,900 species of aerobic and anaerobic Bacteria, Yeasts, and Fungi using the Biolog Gen III Identification Phenotypic technology. Biolog’s advanced phenotypic technology provides valuable information on the properties of strains, in addition to a species-level identification. Molecular methods such as 16s sequencing and MALDI-TOF provide no information about the properties of the strain. Biolog’s carbon source utilisation technology identifies environmental and pathogenic microorganisms by producing a characteristic pattern or “metabolic fingerprint” from discrete test reactions performed within a 96 well microplate. Culture suspensions are tested with a panel of pre-selected assays, then incubated, read and compared to our extensive databases.

Test gram negative and gram positive bacteria in the same test panel TECHNOPATH partners with Biolog for rapid and accurate identification of over 2,900 species of aerobic and anaerobic Bacteria, Yeasts, and Fungi using the Biolog Gen III Identification Phenotypic technology. Biolog’s advanced phenotypic technology provides valuable information on the properties of strains, in addition to a species-level identification. Molecular methods such as 16s sequencing and MALDI-TOF provide no information about the properties of the strain. Biolog’s carbon source utilisation technology identifies environmental and pathogenic microorganisms by producing a characteristic pattern or “metabolic fingerprint” from discrete test reactions performed within a 96 well microplate. Culture suspensions are tested with a panel of pre-selected assays, then incubated, read and compared to our extensive databases.- No Gram Stain

- No pre-tests

- No follow-on tests

- One panel for both Gram Negative & Gram Positive bacteria

- One minute set-up

- Over 1350 species coverage

-

Quantitative spore-forming QC microorganisms for spoilage detection methods Introducing EZ-SPORE, from Microbiologics®. Spore-forming pathogens can present unique challenges for food laboratories that are conducting tests to detect these contaminants. That’s why food microbiology labs across the globe rely on EZ-SPORE quantitative microorganism preparations for validating their spoilage detection methods or for disinfectant qualification studies. EZ-SPORE preparations provide a concentration of 104 CFU per pellet, making microbiological challenge testing for spore-formers quicker and easier. Applications & Test Methods

Quantitative spore-forming QC microorganisms for spoilage detection methods Introducing EZ-SPORE, from Microbiologics®. Spore-forming pathogens can present unique challenges for food laboratories that are conducting tests to detect these contaminants. That’s why food microbiology labs across the globe rely on EZ-SPORE quantitative microorganism preparations for validating their spoilage detection methods or for disinfectant qualification studies. EZ-SPORE preparations provide a concentration of 104 CFU per pellet, making microbiological challenge testing for spore-formers quicker and easier. Applications & Test Methods- Daily food process controls

- Spoilage detection methods

- Disinfectant Qualification Studies

-

QC microorganisms with Green Fluorescent Protein (GFP) markers It’s not uncommon for food samples to inadvertently become contaminated with control strains used in the laboratory. This leads to false-positive results which can have severe financial and regulatory implications. UV-BioTAG, our line of reference strains containing green fluorescent protein (GFP) markers, make it easy to distinguish standard microorganism strains from laboratory control strains. Optimised for highly visible fluorescence, UV-BioTAG strains provide better stability because the GFP marker is integrated into the chromosome rather than the plasmid. With UV-BioTAG, you can quickly and reliably establish whether a positive test result can be traced back to a control strain cross-contamination issue, or if it is from another source. Applications & Test Methods

QC microorganisms with Green Fluorescent Protein (GFP) markers It’s not uncommon for food samples to inadvertently become contaminated with control strains used in the laboratory. This leads to false-positive results which can have severe financial and regulatory implications. UV-BioTAG, our line of reference strains containing green fluorescent protein (GFP) markers, make it easy to distinguish standard microorganism strains from laboratory control strains. Optimised for highly visible fluorescence, UV-BioTAG strains provide better stability because the GFP marker is integrated into the chromosome rather than the plasmid. With UV-BioTAG, you can quickly and reliably establish whether a positive test result can be traced back to a control strain cross-contamination issue, or if it is from another source. Applications & Test Methods- Enumeration Methods

- Detection Methods

- Demonstration of Capability (DOC)

- Media QC

- Validation/Verification

-

Ensure pipettes are performing properly and operator skills are standardized Manage your pipette calibration program and assess operator competency. Used in combination with the Artel PCS, the PCS Software ensures your pipettes and their operators are working together to generate accurate and reproducible results. The PCS Software provides scheduling for pipette calibrations and interim performance verifications; complete documentation and pipette inventory management, even for pipettes calibrated outside of PCS Software – and it’s ideal for standardising pipetting technique and assessing operator competency.

Ensure pipettes are performing properly and operator skills are standardized Manage your pipette calibration program and assess operator competency. Used in combination with the Artel PCS, the PCS Software ensures your pipettes and their operators are working together to generate accurate and reproducible results. The PCS Software provides scheduling for pipette calibrations and interim performance verifications; complete documentation and pipette inventory management, even for pipettes calibrated outside of PCS Software – and it’s ideal for standardising pipetting technique and assessing operator competency. -

For Laboratory, Milk Reception & Process Testing Bentley Instruments have designed devices to automate your milk samples preparation. Agiflex 270 - Homogenisation of samples before analysis Ideal for laboratory use when preparing samples before analysis, the Agiflex 270 is a compact device designed to homogenise all types of containers such as sample trays, racks, flasks and tubes. Adjustable rotation speed from 17 up to 52 rpm. Paraffin Dispenser The paraffin dispenser allows automatic dispensing of melted paraffin in vial or tube racks. Designed specifically to fit your containers, this dispenser is mainly composed of a set of automation and a customised trolley for carrying trays.

For Laboratory, Milk Reception & Process Testing Bentley Instruments have designed devices to automate your milk samples preparation. Agiflex 270 - Homogenisation of samples before analysis Ideal for laboratory use when preparing samples before analysis, the Agiflex 270 is a compact device designed to homogenise all types of containers such as sample trays, racks, flasks and tubes. Adjustable rotation speed from 17 up to 52 rpm. Paraffin Dispenser The paraffin dispenser allows automatic dispensing of melted paraffin in vial or tube racks. Designed specifically to fit your containers, this dispenser is mainly composed of a set of automation and a customised trolley for carrying trays. -

Introducing the Sorter Robot The sorter robot is used to sort the samples and placed them in trays of different colours, depending on the desired analytical chain. Refrigerated to maintain samples quality, it sorts up to 6 different criteria.

Introducing the Sorter Robot The sorter robot is used to sort the samples and placed them in trays of different colours, depending on the desired analytical chain. Refrigerated to maintain samples quality, it sorts up to 6 different criteria. -

Precise determination of somatic cell counts in all types of raw milk Semi-automatic and automatic versions from 100 up to 300 samples/hour The SomaCount FC delivers a rapid and accurate measurement somatic cell counts (SCC) for early mastitis detection in dairy milk. The smallest and most accurate instrument available for the counting of somatic cells in raw milk. Robust and reliable, it is used in both regulatory and high performing dairy laboratories around the globe. Flow cytometry at its best. For any laboratory where precision and performance is essential. It guarantees the accurate counting of somatic cells in milk at a maximum speed of 300 samples/hour (6 versions available: manual, 100, 150, 200, 250 and 300). The automatic SomaCount FC version is coupled to a conveyor system.

Precise determination of somatic cell counts in all types of raw milk Semi-automatic and automatic versions from 100 up to 300 samples/hour The SomaCount FC delivers a rapid and accurate measurement somatic cell counts (SCC) for early mastitis detection in dairy milk. The smallest and most accurate instrument available for the counting of somatic cells in raw milk. Robust and reliable, it is used in both regulatory and high performing dairy laboratories around the globe. Flow cytometry at its best. For any laboratory where precision and performance is essential. It guarantees the accurate counting of somatic cells in milk at a maximum speed of 300 samples/hour (6 versions available: manual, 100, 150, 200, 250 and 300). The automatic SomaCount FC version is coupled to a conveyor system. -

Tray 4x8 for Vials 60ml The Bentley Instruments tray is made of high-resistance ABS plastic (-18°C / +80°C) and identifiable by HF/LF RFID chips or barcode. It lets circulate water in a water bath, is stackable with fall blocking system and positions from 1 to 32 are indicated. Compatible with most vials (84 mm height max - diameter 36 mm max). Compatible with the ILAS 4000 Robot: Automation System for Bacteria Counter and the ILAS 3000 Robot: Automation System for Milk Analysers.

Tray 4x8 for Vials 60ml The Bentley Instruments tray is made of high-resistance ABS plastic (-18°C / +80°C) and identifiable by HF/LF RFID chips or barcode. It lets circulate water in a water bath, is stackable with fall blocking system and positions from 1 to 32 are indicated. Compatible with most vials (84 mm height max - diameter 36 mm max). Compatible with the ILAS 4000 Robot: Automation System for Bacteria Counter and the ILAS 3000 Robot: Automation System for Milk Analysers. -

Introducing the Capper Robot The capper robot is used to dispense the preservative and cap the vials up to a maximum speed of 2500 vials/hour. It can be equipped with an input/output stacker or a gravity roller depending on the space available.

Introducing the Capper Robot The capper robot is used to dispense the preservative and cap the vials up to a maximum speed of 2500 vials/hour. It can be equipped with an input/output stacker or a gravity roller depending on the space available.